Demountable Lining System

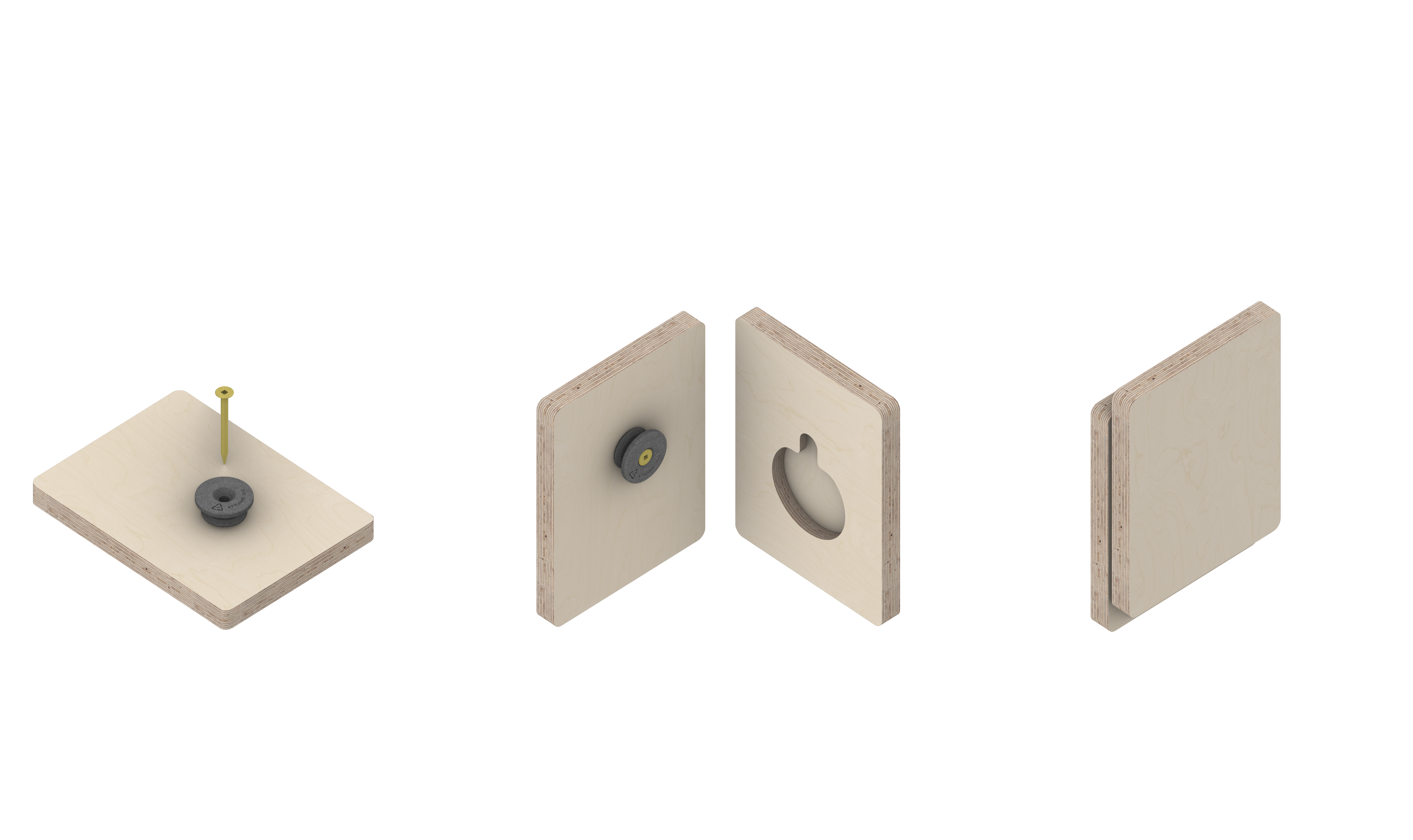

Design: 1-Part (Male) with CNC female - lift-off fixing.

Fixing Method: Screws - one long into frame (typically 40mm 8g CS chip-board screw).

Offset: Flush specification - no gap - lining hard against wall frame. Only works for 16mm or deeper linings.

CAD/CAM Requirements - Lining Side: XF010 CAM Flush Geometry.

CAD/CAM Requirements - Frame Side: A single 3mm dia. pilot hole for clip screw.

Spacing: Max. 600mm centers between clips both horizontally and vertically.

Load Capacity: 30kg per clip.

Usage: For 16mm (5/8 inch) linings. Suitable when the wall thickness needs to be minimised.

Design: 1-Part (Male) with CNC female - lift-off fixing.

Fixing Method: Screws - one long into frame (typically 40mm 8g CS chip-board screw).

Offset: 4mm gap between wall frame and back of linings.

CAD/CAM Requirements - Lining Side: XF010 CAM Typical Geometry.

CAD/CAM Requirements - Frame Side: A single 3mm dia. pilot hole for clip screw.

Spacing: Max. 600mm centers between clips both horizontally and vertically.

Load Capacity: 30kg per clip.

Usage: For any lining 12mm or deeper - allows linings to be easily hung and removed.

Design: 1-Part (Male) with CNC female - lift-off fixing.

Fixing Method: Screws - one long into frame (typically 40mm 8g CS chip-board screw).

Offset: 4mm gap between wall frame and back of linings.

CAD/CAM Requirements - Lining Side: XF010 CAM Rail Geometry.

CAD/CAM Requirements - Frame Side: A single 3mm dia. pilot hole for clip screw.

Spacing: Max. 600mm centers between clips both horizontally and vertically.

Load Capacity: 30kg per clip.

Usage: For any lining 12mm or deeper - allows linings to be easily hung and removed.

Allows linings horozontial location to be adjusted on site via a sliding connection.